- Greater yield, low energy consumption

- High yield, less waste, Great filling accuracy

- Easy installation, use & maintenance

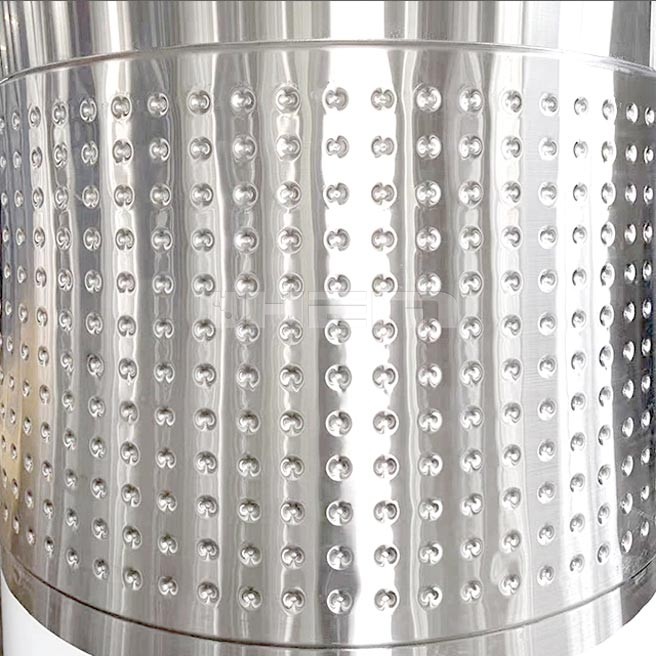

Stainless Steel Wine Fermentation Tank, Fermenter allow you to ferment and carbonate your cider all in one tank. Specialized ASME-stamped high pressure vessels that are designed to suit your beverage cider fermentation process. All the versions of the tank guarantee the utmost hygiene, reliability, practicality in use, safety and durability. Available in various models and sizes to suit a given customer’s specifications, these tanks are made of AISI 304 and 316 stainless steel, paying great attention to the choice of raw materials and to the quality of their manufacture and assembly.

| Model | Dimension (mm) | Height (mm) | Legs | Cooling area (m2) |

| WT1 | Φ920*1500 | 2180 | 3 | 1.4 |

| WT2 | Φ1270*1610 | 2600 | 3 | 2.2 |

| WT3 | Φ1500*1830 | 3000 | 4 | 3 |

| WT4 | Φ1600*2000 | 3250 | 4 | 4 |

| WT5 | Φ1600*2440 | 3650 | 4 | 5 |

| WT6 | Φ1800*2440 | 3500 | 4 | 5.5 |

| WT8 | Φ1820*3050 | 4650 | 4 | 7 |

| WT10 | Φ1900*3660 | 5050 | 4 | 8.5 |

| WT12 | Φ1900*4270 | 5750 | 4 | 10 |

| WT15 | Φ2000*4880 | 5950 | 4 | 12 |

| WT20 | Φ2300*4880 | 6100 | 4 | 14 |

| WT25 | Φ2600*4880 | 6050 | 4 | 15 |

| WT30 | Φ2600*5500 | 6550 | 4/6 | 18 |

| Item | Production capacity | Volume in US Gallon | Heating area | Tank diameter | Height |

| FT-500 | 500L/day | 132 US Gallon | 1.8m2 | 1160mm | 2300mm |

| FT-5BBL | 5BBL/day | 155 US Gallon | 1.9m2 | 1200mm | 2350mm |

| FT-600 | 600L/day | 158 US Gallon | 2.0m2 | 1220mm | 2350mm |

| FT-700 | 700L/day | 185 US Gallon | 2.4m2 | 1260mm | 2380mm |

| FT-800 | 800L/day | 212 US Gallon | 2.5m2 | 1260mm | 2400mm |

| FT-7BBL | 7BBL/day | 216 US Gallon | 2.5m2 | 1280mm | 2450mm |

| FT-1000 | 1000L/day | 264 US Gallon | 2.6m2 | 1360mm | 2500mm |

| FT-10BBL | 10BBL/day | 310 US Gallon | 2.8m2 | 1460mm | 2700mm |

| FT-1500 | 1500L/day | 396 US Gallon | 3.2m2 | 1520mm | 2900mm |

| FT-2000 | 2000L/day | 528 US Gallon | 3.6m2 | 1560mm | 2850mm |

| FT-2500 | 2500L/day | 660 US Gallon | 3.8m2 | 1650mm | 3200mm |

| FT-3000 | 3000L/day | 792 US Gallon | 4.5m2 | 1760mm | 3800mm |

| FT-4000 | 4000L/day | 1057 US Gallon | 4.9m2 | 1900mm | 4100mm |

| FT-5000 | 5000L/day | 1320 US Gallon | 7.2m2 | 1960mm | 4400mm |